A September Wedding to Remember in Iowa

-

A September Wedding to Remember in Iowa

Todd Swank's Diary Entry for September 14, 2025

Luke invited us over for Monday Night Football with his roomm...

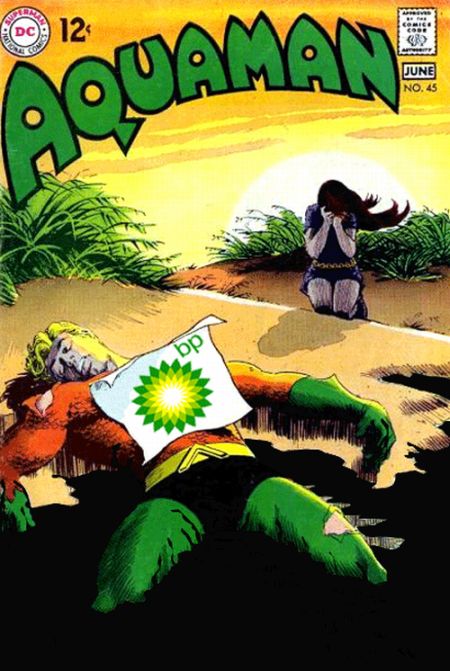

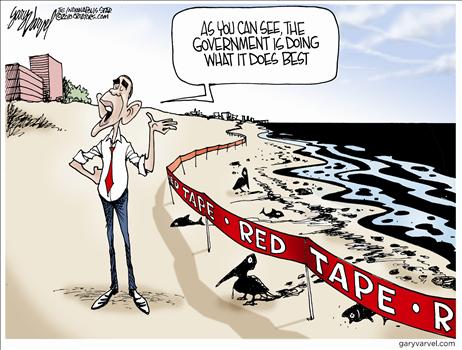

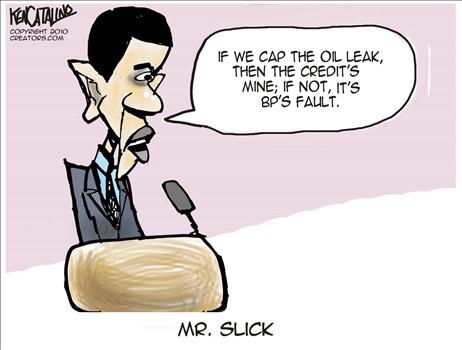

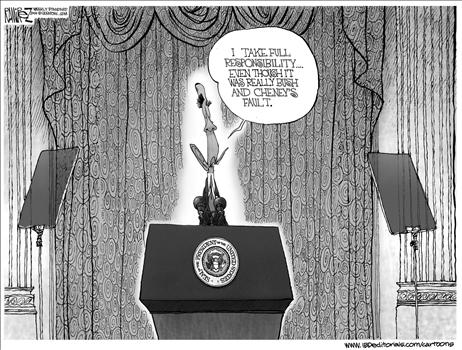

Showing posts with label BP Oil Spill. Show all posts

Showing posts with label BP Oil Spill. Show all posts

July 25, 2010

July 6, 2010

June 30, 2010

June 27, 2010

Water Powered Car

They just announced that they finally have an auto that will run on water.

Of course it will only run on the water from the gulf..

June 26, 2010

What 25,000 Barrels oil looks like!

Putting BP's 25,000 barrels/day spill in perspective:

This is what 25,000 barrels of oil looks like if it were stacked on the ground. This is what is gushing into the Gulf.

Every. Single. Day!

June 20, 2010

June 16, 2010

The Best BP Oil Spill Posts I Have So Far....

Here's a link to all my posts on the BP Oil Spill.

http://shortarmguy.blogspot.com/search/label/BP%20Oil%20Spill

The Good, the Bad, the Funny!

http://shortarmguy.blogspot.com/search/label/BP%20Oil%20Spill

The Good, the Bad, the Funny!

Send your best BP Oil Spill post entries to shortarmguy@aol.com

I'll post the best ones received on this website.

Thanks!!

Shortarmguy

Greatest Poster Ever! While Rome is Burning....

Party guests from left to right: Tim Geithner, John Kerry, KSM, Oprah, Nancy Pelosi, Joe Biden, Axelrod, Barack Obama, Michelle Obama, Hillary Clinton, Party Crashers #1, Rahm Emanuel, Eric Holder, Party Crashers #2, Harry Reid, John Edwards, Bluto, Andy Stern, Bill Clinton, Chris Matthews, Keith Olbermann, Barney Frank, Kevin Jennings

Statues left to right: Che Guevara, Saul Alinsky, Obama, Chairman Mao, Lenin

We're all going to die!

Gulf oil volcano---It's far, FAR worse than you imagined--What is and what will be

Oil Volcano Pressure Too Strong For Containment

Dr. James P. Wickstrom

6-9-10

It has been estimated by experts that the pressure which blows the oil into the Gulf waters is estimated to be between 20,000 and 70,000 PSI (pounds per square inch). Impossible to control.

What US Scientists Are Forbidden To Tell The Public About The Gulf

What you are about to read, is what the scientists in the United States are not allowed to tell you in great fear of the Obama administration.

They are under the threat of severe repercussions to the max.. Scientists confirming these findings cannot be named due to the above, but what they believe, they want to be known by all.

Take a U. S. map, lay it flat and measure inland just the minimum 50 miles of total destruction all around the Gulf of Mexico as to what you will read below.

The carnage to the United States is so staggering, it will take your breathe away.

Should what the scientists who are trying to warn everyone about be even close to being true... all of Florida will be completely destroyed as will everyone and everything on it.

You decide!! Everyone has the right to read what I have just written in this article, as well as to what is written below by the scientists who the Obama administration and BP are trying to shut up.

Please share with as many as you can.

--Dr. James P. Wickstrom

SUMMARY OF WHAT IS HAPPENING

The estimated super high pressure release of oil from under the earth's crust is between 80,000 to 100,000 barrels per day.

The flow of oil and toxic gases is bringing up with it... rocks and sand which causes the flow to create a sandblasting effect on the remaining well head device currently somewhat restricting the flow, as well as the drilled hole itself.

As the well head becomes worn it enlarges the passageway allowing an ever-increasing flow. Even if some device could be placed onto the existing wellhead, it would not be able to shut off the flow, because what remains of the existing wellhead would not be able to contain the pressure.

The well head piping is originally about 2 inches thick. It is now likely to be less than 1 inch thick, and thinning by each passing moment. The oil has now reached the Gulf Stream and is entering the Oceanic current which is at least four times stronger than the current in the Gulf, which will carry it throughout the world within 18 months.

The oil along with the gasses, including benzene and many other toxins, is deleting the oxygen in the water. This is killing all life in the ocean. Along with the oil along the shores, there will be many dead fish, etc. that will have to be gathered and disposed of.

SUMMARY OF EXPECTATIONS

At some point the drilled hole in the earth will enlarge itself beneath the wellhead to weaken the area the wellhead rests upon. The intense pressure will then push the wellhead off the hole allowing a direct unrestricted flow of oil, etc.

The hole will continue to increase in size allowing more and more oil to rise into the Gulf. After several billion barrels of oil have been released, the pressure within the massive cavity five miles beneath the ocean floor will begin to normalize.

This will allow the water, under the intense pressure at 1 mile deep, to be forced into the hole and the cavity where the oil was. The temperature at that depth is near 400 degrees, possibly more.

The water will be vaporized and turned into steam, creating an enormous amount of force, lifting the Gulf floor. It is difficult to know how much water will go down to the core and therefore, its not possible to fully calculate the rise of the floor.

The tsunami wave this will create will be anywhere from 20 to 80 feet high, possibly more. Then the floor will fall into the now vacant chamber. This is how nature will seal the hole.

Depending on the height of the tsunami, the ocean debris, oil, and existing structures that will be washed away on shore and inland, will leave the area from 50 to 200 miles inland devoid of life. Even if the debris is cleaned up, the contaminants that will be in the ground and water supply will prohibit re-population of these areas for an unknown number of years.

(End of scientists information release.) From Tom Buyea FL News Service

BP got the oil leak stopped !!

BP Got the oil leak stopped.

They lowered a giant wedding ring around the well and it quit putting out!

June 13, 2010

June 5, 2010

Put The Oil Spill In Perspective

SEE and compare the oil spill to your area...Puts it in Perspective how big it is !

Click on "move oil spill" and then type in your area. Amazing to put it in reference to a area you know. Kinda Scary...

June 3, 2010

Shortcuts lead to tragedy. Best explanation of the oil spill I've seen yet!

I received this email at work from a friend of mind and I found it to be quite informative...

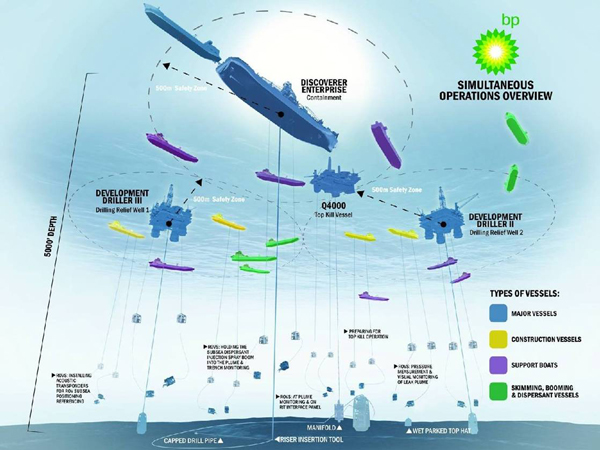

When there are shortcuts and things go very very wrong, it is costly business. Check out the SIMOPS currently underway ......

Oil Operations at Transocean Deepwater Horizon Disaster Location

Here is the latest story which sounds pretty feasible!!!

The following is my theory on what happened on April 20th. I have listed factual information to the best of my knowledge, and base this theory on 33 years of experience working on these rigs, with 16 years working as a consultant worldwide. The contractor (Transocean in this case) typically does not do anything without direction and approval from the operator (BP in this case). I believe that there was nothing wrong with the BOP, or the conduct of the crews prior to the catastrophic failure. If any operator drills a similar well using the same flawed casing and cement program, the same results will be very possible.

The well was drilled to 18,360 ft and final mud weight was 14.0 ppg. The last casing long string was 16 inch and there were 3 drilling liners (13 5/8”, 11 7/8” and 9 7/8”) with 3 liner tops. A 9-7/8” X 7” tapered casing long string was run to TD. The bottom section of casing was cemented with only 51 barrels of light weight cement containing nitrogen, a tricky procedure, especially in these conditions.

The casing seal assembly was set in wellhead and pressure tested from above to 10,000 psi. Reportedly, a lock down ring was not run on the casing hanger. The casing string was pressure tested against the Shear rams, only 16.5 hours after primary cement job. A negative test on the wellhead packoff was performed.

The rig crew was likely lead to believe that the well was successfully cemented, capped and secured. Normally a responsible operator will not remove the primary source of well control (14.0 ppg drilling mud) until such conditions were met. However, the crews were given the order to displace heavy mud from riser with seawater, prior to setting the final cement plugs. They were pumping seawater down the drill string and sending returns overboard to workboat, so there was limited ability to directly detect influx via pit level. This is the fastest way to perform the displacement operation, and the method was likely directed and certainly approved by operator. There was a sudden casing failure during this displacement procedure that allowed the well to unload, with ignition of gas and oil. Evidently, the crew was able to get the diverter closed based on initial photographs, showing flames coming out of diverter lines.

It is likely that pressure built up between the 9 7/8” and 16" casing under the casing hanger, due to gas migration from the pay zone. Based on reported mud weight, the reservoir formation pressure is in excess of 13,000 psi. The pressure building in the cross sectional area below the casing hanger would have increased casing tension and caused casing to collapse and part (rapidly separate) at a connection, probably a joint or two (50’ or 90’) below wellhead. The collapse pressure for 62.8 ppf 9-7/8” casing is +/- 10,300 psi. However, the collapse resistance of casing is considerably reduced in presence of axial stress (i.e. tension). Engineers - see formula from API bulletin 5C3, section 2.1.5 and run the math. The well then came in violently through parted casing and caused the blowout. Without lockdown ring on hanger, the casing hanger and joint(s) were slingshot up into BOP. That would explain why all components of the BOP are unable to seal or shear. The parted casing section remains across all BOP ram cavities and probably all the way up into the riser.

Shortcut #1: Running a tapered long string rather than a liner with 9-7/8” liner top packer, followed by tieback string and pumping heavy cement all the way to seabed. Perhaps the original permits for this casing program were based on a planned appraisal well, and changed midstream to a producer well, then hastily approved by the complacent or under-staffed MMS. This tragic shortcut may have saved about 1.5 rig days.

Shortcut #2: Insufficient time was used to cure the mud losses prior to cementing the open hole reservoir section, depending instead on using lightweight cement to prevent losses to the formation.

Shortcut #3: The nitrified primary cement job. This is difficult to pull off, even under ideal conditions.

Shortcut #4: Hanger without lock ring may have used due to the previously unplanned long string, and to avoid waiting for hanger with lock ring to be fabricated or prepared.

Shortcut #5: No cement evaluation logs were performed after a job with known high calculated risk (mud losses to formation). This shortcut may have saved 8 hours of rig time.

Shortcut #6: Pressure testing casing less than 24 hours after cement in place can expand the casing before the cement is fully set. This shortcut can “crack” the cement and create a micro annulus which will allow gas migration.

Shortcut #7: Displacing 14 ppg mud from 8000 ft MDRT with 8.7 ppg seawater, less than 20 hours after primary cement is in place. How many tested and proven barriers can you count? I count zero satisfactory barriers. Industry standards dictate that at least two tested (to maximum anticipated pressure) barriers are in place prior to removing the primary source of well control (weighted mud or brine).

When there are shortcuts and things go very very wrong, it is costly business. Check out the SIMOPS currently underway ......

Oil Operations at Transocean Deepwater Horizon Disaster Location

Here is the latest story which sounds pretty feasible!!!

The following is my theory on what happened on April 20th. I have listed factual information to the best of my knowledge, and base this theory on 33 years of experience working on these rigs, with 16 years working as a consultant worldwide. The contractor (Transocean in this case) typically does not do anything without direction and approval from the operator (BP in this case). I believe that there was nothing wrong with the BOP, or the conduct of the crews prior to the catastrophic failure. If any operator drills a similar well using the same flawed casing and cement program, the same results will be very possible.

The well was drilled to 18,360 ft and final mud weight was 14.0 ppg. The last casing long string was 16 inch and there were 3 drilling liners (13 5/8”, 11 7/8” and 9 7/8”) with 3 liner tops. A 9-7/8” X 7” tapered casing long string was run to TD. The bottom section of casing was cemented with only 51 barrels of light weight cement containing nitrogen, a tricky procedure, especially in these conditions.

The casing seal assembly was set in wellhead and pressure tested from above to 10,000 psi. Reportedly, a lock down ring was not run on the casing hanger. The casing string was pressure tested against the Shear rams, only 16.5 hours after primary cement job. A negative test on the wellhead packoff was performed.

The rig crew was likely lead to believe that the well was successfully cemented, capped and secured. Normally a responsible operator will not remove the primary source of well control (14.0 ppg drilling mud) until such conditions were met. However, the crews were given the order to displace heavy mud from riser with seawater, prior to setting the final cement plugs. They were pumping seawater down the drill string and sending returns overboard to workboat, so there was limited ability to directly detect influx via pit level. This is the fastest way to perform the displacement operation, and the method was likely directed and certainly approved by operator. There was a sudden casing failure during this displacement procedure that allowed the well to unload, with ignition of gas and oil. Evidently, the crew was able to get the diverter closed based on initial photographs, showing flames coming out of diverter lines.

It is likely that pressure built up between the 9 7/8” and 16" casing under the casing hanger, due to gas migration from the pay zone. Based on reported mud weight, the reservoir formation pressure is in excess of 13,000 psi. The pressure building in the cross sectional area below the casing hanger would have increased casing tension and caused casing to collapse and part (rapidly separate) at a connection, probably a joint or two (50’ or 90’) below wellhead. The collapse pressure for 62.8 ppf 9-7/8” casing is +/- 10,300 psi. However, the collapse resistance of casing is considerably reduced in presence of axial stress (i.e. tension). Engineers - see formula from API bulletin 5C3, section 2.1.5 and run the math. The well then came in violently through parted casing and caused the blowout. Without lockdown ring on hanger, the casing hanger and joint(s) were slingshot up into BOP. That would explain why all components of the BOP are unable to seal or shear. The parted casing section remains across all BOP ram cavities and probably all the way up into the riser.

Shortcut #1: Running a tapered long string rather than a liner with 9-7/8” liner top packer, followed by tieback string and pumping heavy cement all the way to seabed. Perhaps the original permits for this casing program were based on a planned appraisal well, and changed midstream to a producer well, then hastily approved by the complacent or under-staffed MMS. This tragic shortcut may have saved about 1.5 rig days.

Shortcut #2: Insufficient time was used to cure the mud losses prior to cementing the open hole reservoir section, depending instead on using lightweight cement to prevent losses to the formation.

Shortcut #3: The nitrified primary cement job. This is difficult to pull off, even under ideal conditions.

Shortcut #4: Hanger without lock ring may have used due to the previously unplanned long string, and to avoid waiting for hanger with lock ring to be fabricated or prepared.

Shortcut #5: No cement evaluation logs were performed after a job with known high calculated risk (mud losses to formation). This shortcut may have saved 8 hours of rig time.

Shortcut #6: Pressure testing casing less than 24 hours after cement in place can expand the casing before the cement is fully set. This shortcut can “crack” the cement and create a micro annulus which will allow gas migration.

Shortcut #7: Displacing 14 ppg mud from 8000 ft MDRT with 8.7 ppg seawater, less than 20 hours after primary cement is in place. How many tested and proven barriers can you count? I count zero satisfactory barriers. Industry standards dictate that at least two tested (to maximum anticipated pressure) barriers are in place prior to removing the primary source of well control (weighted mud or brine).

May 31, 2010

NASA satellites are capturing images of the oil spill

Sad time for all...

— May 27, 2010 — Two NASA satellites are capturing images of the oil spill in the Gulf of Mexico, which began April 20, 2010 with the explosion of the Deepwater Horizon oil rig. This short video reveals a space-based view of the burning oil rig and, later, the ensuing oil spill

through May 24. The timelapse uses imagery from the MODIS instrument, on board NASA's Terra and Aqua satellites. The oil slick appears grayish-beige in the image and changes due to changing weather, currents, and use of oil dispersing chemicals.

— May 27, 2010 — Two NASA satellites are capturing images of the oil spill in the Gulf of Mexico, which began April 20, 2010 with the explosion of the Deepwater Horizon oil rig. This short video reveals a space-based view of the burning oil rig and, later, the ensuing oil spill

through May 24. The timelapse uses imagery from the MODIS instrument, on board NASA's Terra and Aqua satellites. The oil slick appears grayish-beige in the image and changes due to changing weather, currents, and use of oil dispersing chemicals.

Subscribe to:

Posts (Atom)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)